MBA 646 Operations and Supply Chain Management

| Title: | |||

| Course: MBA 646 Operations and Supply Chain Management | |||

| Academic Year: Fall 2022-2023 cycle 2 | Course Credit Hours: 3 | ||

| Assessment Type: | Case study |

| Responsibility: | Individual |

| Deliverable: | Report |

| Total Marks: | 15 |

| Hand in to: | Instructor |

| Submission Date: | |

| Send by email only. |

| General Description:

Read the uploaded case study and send your answer by email. Blockchain in Supply Chain Management: Australian Manufacturer Case Study |

| Learning Outcome/s Assessed:

This assessment tool is applying learning outcomes 1,2, 3,4 and 5 given in the course syllabus. . |

|

Title: | ||

| Course: MBA 646 Operations and Supply Chain Management | |||

| Academic Year: Fall 2022-2023 cycle 2 | Course Credit Hours: 3 | ||

| Assessment Type: | Case study |

| Responsibility: | Individual |

| Deliverable: | Report |

| Total Marks: | 15 |

| Hand in to: | Instructor |

| Submission Date: | |

| Send by email only. |

| General Description:

Read the uploaded case study and send your answer by email. Blockchain in Supply Chain Management: Australian Manufacturer Case Study |

| Learning Outcome/s Assessed:

This assessment tool is applying learning outcomes 1,2, 3,4 and 5 given in the course syllabus. . |

Blockchain in Supply Chain Management: Australian Manufacturer Case Study

![]()

![]()

![]() Elias Abou Maroun1(&) , Jay Daniel2 , Didar Zowghi1 , and Amir Talaei-Khoei3

Elias Abou Maroun1(&) , Jay Daniel2 , Didar Zowghi1 , and Amir Talaei-Khoei3

1 Faculty of Engineering and IT, University of Technology Sydney, Sydney, Australia

Elias.AbouMaroun@student.uts.edu.au, Didar.Zowghi@uts.edu.au

2 Derby Business School, University of Derby, Derby, UK

3 Department of Information Systems, Ansari College of Business, University of Nevada, Reno, NV, USA

Abstract. The recent explosion of interest around Blockchain and capabilities of this technology to track all types of transaction more transparently and securely motivate us to explore the possibilities Blockchain offers across the supply chain. This paper examines whether Blockchain makes a good fit for use in an Australian manufacturer supply chain. To address this, the research uses Technology Acceptance Model (TAM) as a framework from the literature. Blockchain allows us to have permissioned or permission-less distributed led- gers where stakeholders can interact with each other. It details how Blockchain works and the mechanism of hash algorithms which allows for greater security of information. It also focuses on the supply chain management and looks at the intricacies/complexity of a manufacturers supply chain. We present a review of the processes in place of an electrical manufacturer and the problems faced in the supply chain. A model is proposed in using public and private Blockchains to overcome these issues. The proposed solution has the potential to bring greater transparency, validity across the supply chain, and improvement of communication between stakeholders involved. We also point out some potential issues that should be considered if adopting Blockchain.

Keywords: Manufacturing supply chain management Blockchain Distributed ledger

· ·

Introduction

The amount of data being created and collected is growing at an exponential rate. This growth is primarily due to technology advances in devices which are known as the ‘Internet of Things’ (IOT) and the significance of computer power and availability of storage resources. Data is evolving and becoming part of everyday human activity, from product goods being sourced, product manufacturing and delivery of products to

© Springer Nature Switzerland AG 2019

H.-P. Lam and S. Mistry (Eds.): ASSRI 2018, LNBIP 367, pp. 93–107, 2019.

https://doi.org/10.1007/978-3-030-32242-7_8

consumers. The increase in data has provided opportunity for new approaches and techniques to create, store, analyse and obtain useful insight from the supply chain.

Supply chains are known to be large, complex and often unpredictable as they include four essential functions: sales, distribution, production, and procurement. They represent all the links that are involved in the sourcing of raw materials, manufacturing of goods, and the distribution of a finished product to the end consumer. Operational management of supply chains requires methods and tools to enable organisations to better understand how unexpected disruptions occur and what impacts they will have on the flow of goods to customer demand. Supply chain visibility provides opportu- nities for managers not only to plan efficiently but also to react appropriately to the accurate information [1].

Supply chains can span from over hundreds of stages and multiple geographical locations which makes it complex to trace events in the supply chain and investigate any issues. To date, customers have no reliable way to validate the true value and authenticity of a product purchased due to the lack of transparency, tracking, recording and sharing of information. The lack of transparency causes an absence of information from being shared about the manufacturing process of goods, assembly, delivery and certification of materials used that might pose risks and issues in the supply chain. This also poses a risk to fraud occurring in the supply chain such as counterfeiting of products, and the accountability of any illicit activities that may occur. Generally, questions are raised when manufacturing goods such as where are these components coming from? Do they meet the expected standards and are they safe?

Supply chains suffer from inefficiencies in the recording of assets such as pallets, trailers and containers that are continuously moving between supply chain nodes. There are issues in the tracking of purchase orders, receipts, shipment notifications and other trade related documents. The lack of assigning or verification of certain properties of the physical products or the linking of goods to serial numbers, bar codes or digital tags like radio frequency identification (RFID). Current Supply chain systems hold key data relating to each stage of the supply chain, people working in different stages must use the same system to update or complete the data of the process. This localized system typically an enterprise resource system (ERP) are comprised of localized possession of the company data and does not hold the complete stages of the supply chain. The objective is to bridge the gap between the different stages of the supply chain using Blockchain for supply chain management.

The Blockchain technology allows for data to be written in files called Blocks. The Blockchain technology can record transactions of almost any type based on certain conditions that are agreed on by stakeholder which can solve record keeping issues, however, computer professionals remain skeptical about relying on this technology for complex and long-term transactions management. They remain unsure about the preservation ability of the system for trusted digital records. Lemieux [2] and [3] identify threats and vulnerability of Blockchain as control base threats (Control of Blockchain, and Control of record creation outside of Blockchain), attack base threats (Man-in-the-middle attack, SYN Flood attack, Sybil attack, and Audit server attack), system base threats (Timing errors, and Preservation of original records), and process base threats (Change of bit rot to encryption, Collision of hashes, and encryption code Breakage). The Blockchain enables different organisations to collaborate and validate

entries in the Blockchain hence giving stakeholders visibility of the overall activities taking place. This paper proposes using Blockchain technology to enable various upstream and downstream parties in supply chain to verify the authenticity of each individual Block and provide transparency across different stages of the supply chain. Various parties in the supply chain first provide input and agree on the content of a Block. Once in place, the Blockchain will include a set of constraints which cannot be violated by any Block.

An Australian electrical manufacturer (AEM) has been chosen to address the issues of traceability, transparency and inefficiencies which are common in supply chain management. The supply chain chosen is also common among the fast-moving con- sumer goods industry. The remainder of this paper is organised as follows: Sect. 2 the related work is reviewed. The proposed model and case study are discussed in Sects. 3 and 4, respectively. Finally, Sect. 5 provides discussion, conclusion and future work in this area.

Literature Review

Recently, more and more applications are being created based on Blockchain tech- nology [4]. Initially, the Blockchain technology was the key technique behind Bitcoin [5]. Bitcoin is a popular form of digital cryptocurrency which was developed in 2008 by “Satoshi Nakamoto”. The technology underlying Bitcoin is named Blockchain which acts as the payments layer for Internet. This new form of general computational substrate is a mechanism for updating truth states in distributed computer networks [6]. A recent survey has divided Blockchain-inspired technologies into two [7] fully decentralized permission-less ledgers, (e.g., Bitcoin, Ethereum), and semi-centralized permissioned ledgers (e.g. Ripple). These ledgers are known as ‘distributed ledgers’. Lack of studies in the applicability of Blockchain technology motivated researchers to find the possibilities of this technology in other areas. Ølnes [8] investigated the possible application of this technology in electronic governments. To this end, a case of storing academic certificates on the Blockchain was presented to highlight the inno- vation potential of the new technology for storing and securing vital information. He concluded that although Blockchain is a promising technology for validating many types of persistent documents, still there is a long way to implement this technology in public sector. Nevertheless, the implications and limitations of using such technologies as a software connector had been elaborated as well. Dierksmeier and Seele [9] pro- vided rationale to address the impact of “Blockchain technology” on the nature of financial transactions from a business ethics perspective. They combined different business and society levels such as micro, meso, and macro to propose a framework for assessing current status of cryptocurrencies ethical debates.

-

- Blockchain

Several studies have attempted to find the performance and impacts of Blockchain in comparison with other systems. Focusing on their scalability limits. Vukolić [10] made a comparison between proof-of-work (PoW)-based Blockchains to those based on

Byzantine fault-tolerant (BFT) state machine. To tackle these limits, they reviewed recent proposed solutions developed for the ultimate Blockchain fabric. Based on the experience in several Blockchain projects, Xu, Pautasso [4] studied the architectural decisions in a system. In the situation whether to employ a decentralized Blockchain as opposed to other software solutions such as a traditional shared data storage.

Lemieux [2] studied to what extent Blockchain technology creates trustworthy digital records by applying a risk-based assessment method to evaluate the imple- mentation of Blockchain technology in land registry system. The results indicated that although Blockchain technology can be used to address issues associated with infor- mation integrity in the present and near term [2], the reliability of information and maintaining long-term preservation could not be guaranteed. In 2016, a study was conducted on interdisciplinary fields of Blockchain and the healthcare system to pre- vent data sharing and improve patients’ privacy by enabling them to own, control and share their own data easily and securely. In this regard, an App named Healthcare Data Gateway (HGD) that was designed based on Blockchain architecture has been devel- oped by Yue, Wang [11] with the capability to organize and categorize all kinds of personal healthcare data and secure Multi-Party Computing.

The solution that Blockchain proposes is the use of a timestamp server that takes the hash of a Block of items, timestamps it, and widely publishes the hash [12]. This involves using hash algorithms to find a specific value. The Block is only accepted by users if all transactions in it are valid and the Bitcoins have not been spent previously [12]. Users show their acceptance by using the newly found hash in the “previous hash” section of the next Block they attempt to generate. This adds a new Block to the chain (the Block chain or transaction log). The chain thus contains the entire history of all transactions that have been carried out in the network [12]. The first Block of a Blockchain is called the genesis and has no parent as each Block on the Blockchain is referenced or identified by its hash [13]. A Blocks hash is typically a one-way hashing function used that maps an input to an output. There are different types of hash algorithms which may be used. For example, applying the SHA-1 hash algorithm function to a string “hello Blockchain” will produce the following hash value “bdb9814fb8929bd976a8ba1a4e037992ca7111e0”.

Applying a hash function to a string will return a new string and if that string remains the same, the same hash will be produced. Data integrity is optimal as one can verify their hash with a hash key that has been given when downloading a file. This is done by comparing both hash keys as this ensures the file has not been tampered with and every byte of data is exactly the same. The Blockchain, also known as the con- sensus protocol [14], serves as a public or private ledger for any transactions, and every user is able to connect to the network and send transactions to the Blockchain, verify transactions and create new Blocks. It is a data structure which is used to ensure secure and tamper proof distributed ledgers. Each Blockchain is made up of Blocks which are linked to a previous Block and contain exclusive data and a timestamp.

To form a Blockchain, sequences of bits encrypted as a Block are stored by net- worked computers (nodes) within a system and are chained together. The veracity of new Blockchain links are established by a decentralized mining process. Before new links are formally added to the Blockchain, a meticulous mathematical hash is derived by competing mining computers to verify their content [12]. When a bitcoin is

transferred to the next user, it gets digitally signed with a hash value denoting the precedent transaction and the public key of the next owner. The hash is defined as a chain of signatures. These can be verified by the payee to authenticate the chain of ownership [12]. To become part of the peer-to-peer network, one needs to have a client software that runs on either an own device or on a cloud service [12]. Nodes in the network only accept the first authenticated transaction and reject any subsequent attempts to make any further transactions to stop malicious users from rewriting their history.

-

- Applications of Blockchain

Most current cloud-based applications rely on a single trusted controlling organisation that manages the network, storage and compute. This approach may be desirable for some applications however in some cases, a decentralized and distributed approach is better suited. For example, Walmart, the world’s largest retailer is conducting pilot tests for worldwide supply chain food traceability [15]. The increasing development of the digital economy, the internet of things (IOT) and the growing use of sensors providing information in supply chains is providing Blockchain leverage to streamline and create an efficient supply chain track and trace management system. There are examples of Blockchain technology going beyond the realm of currencies and banking and evolving into industries such as real estate, for land registry systems, digital healthcare record systems [16] and government identification and registry systems [13]. Many businesses have already begun accepting Bitcoin in their payments including PayPal, Apple, and Universal Air Travel Plan (UATP). In addition, firms such as Citi Corp, Goldman Sachs, Barclays, Overstock, and IBM started to pay attention to cryptocurrencies. Governments around the world are creating policies for cryptocurrency, including Brazil, Russia, India, China and South Africa (BRICS). The BRICS business council is also debating the possibility in creating a BRICS cryptocurrency as an alternative to other financial instruments Council [17]. USA has already deployed bitcoin technology for interbank payments and Australia has already began a trial for bank guarantees using Blockchain technology [18]. Interoperability challenges between bitcoin and other ledger assets between multiple Blockchains have been addressed by creating mechanisms such as Pegged Sidechains [19].

-

- Benefits and Limitations

Processing transactions over a distributed network without a central node functioning as a bank or clearing house reduces the cost of the transactions. Processing transactions using the Blockchain is less costly than the traditional approach Chuen and Deng [20]. However, the validation and verification of data comes with high hardware and energy costs [21]. The business of processing transactions tends to be highly concentrated and can be impacted with waiting for stakeholders executing their due diligence actions. With Blockchains, business transactions can be made to run in parallel potentially unleashing huge efficiency dividends e.g. businesses can unlock capital or value quickly rather than waiting for a transaction to be completed. The transactions volume handled by each payment processor can be increased manyfold but the added

coordination costs to overcome network effects need to be considered. The drawback of a single Blockchain is the exponential increase in the cost and time per Block and hence per transaction. However, there is an argument that the technology’s primary benefit is security and not efficiency Dirkmaat [22]. The ability to use multiple Blockchains to improve efficiency requires interoperability between different Block- chains. Blockchains need to be able interact with each other as a single Blockchain alone has limited performance [23]. Various studies such as [24], [25] and [26] have established a framework to exchange information between multiple Blockchains. Promising solutions also proposed to address this challenge by storing actual data in sidechains and operating the Blockchain as a control layer rather than as a storage layer [27]. The added benefits of using Blockchain is the reliability, where a single point of failure does not affect the whole operation of the network. The various works reviewed in this study show that Blockchain is a promising technology for a wide area of services.

-

- Supply Chain Management

Supply chain management comprises of a series of entities, including people, systems, knowledge and processes. In a large supply chain, it is difficult to have an overall picture of all transactions within the chains [28]. This data is typically stored in multiple systems which are only accessible by certain participants in the supply chain. Several papers [27, 29, 30] investigate how supply chain is becoming transformed through Blockchain technology. The digital supply chain integration is becoming increasingly dynamic. Blockchain technology is providing a major advance for supply chains in assisting the delivery of source, process and products. The adoption of Blockchain technology should make the process faster and make transactional records more robust and reliable [30]. Rather than limiting a supply chain to regions, the utilisation of Blockchain will make it possible to have global production chains that are visible remotely. This is in line with what Kietzman [31] observed the current unseen dimensions from the vast network of retailers, distributors, transporters, storage facil- ities, and suppliers that participate in design, production, delivery and sales will be transparent. Organisations will have a competitive advantage of open, transparent supply chains and sustainable manufacturing. Models have been created for tracking agriculture in the supply chain [32]. This new model demonstrates the concept of circular economy and eliminates many of the disadvantages of the supply chain such as the cost to exchange between different parties in the supply chain. An overview of the proposed application of Blockchain in supply chain is illustrated in our model.

-

- Technology Acceptance Model (TAM)

The technology acceptance model (TAM) was originally developed through a doctoral dissertation [33] and well cited in a MIS quarterly article [34]. Technology acceptance model is an information systems theory that models the decision-making process by which users may or may not adopt and implement new technology. There are two major considerations in TAM, perceived ease of use and perceived usefulness by the intended user.

Perceived ease of use (PEU) is defined by [34] as “the degree to which a person believes using the system will be free of effort.” The perceived usefulness (PU) is defined by [34], as “the extent to which a person believes that using a particular technology will enhance his/her job performance”. Technology acceptance models have been used to analyse the acceptance of technology in a variety of domains, from healthcare [35], a physician’s choice and acceptance of the use of smartphones. Technology acceptance model has also been helpful in education learning [36], where scholars have examined student and faculty adoption of online learning [37].

Proposed Model

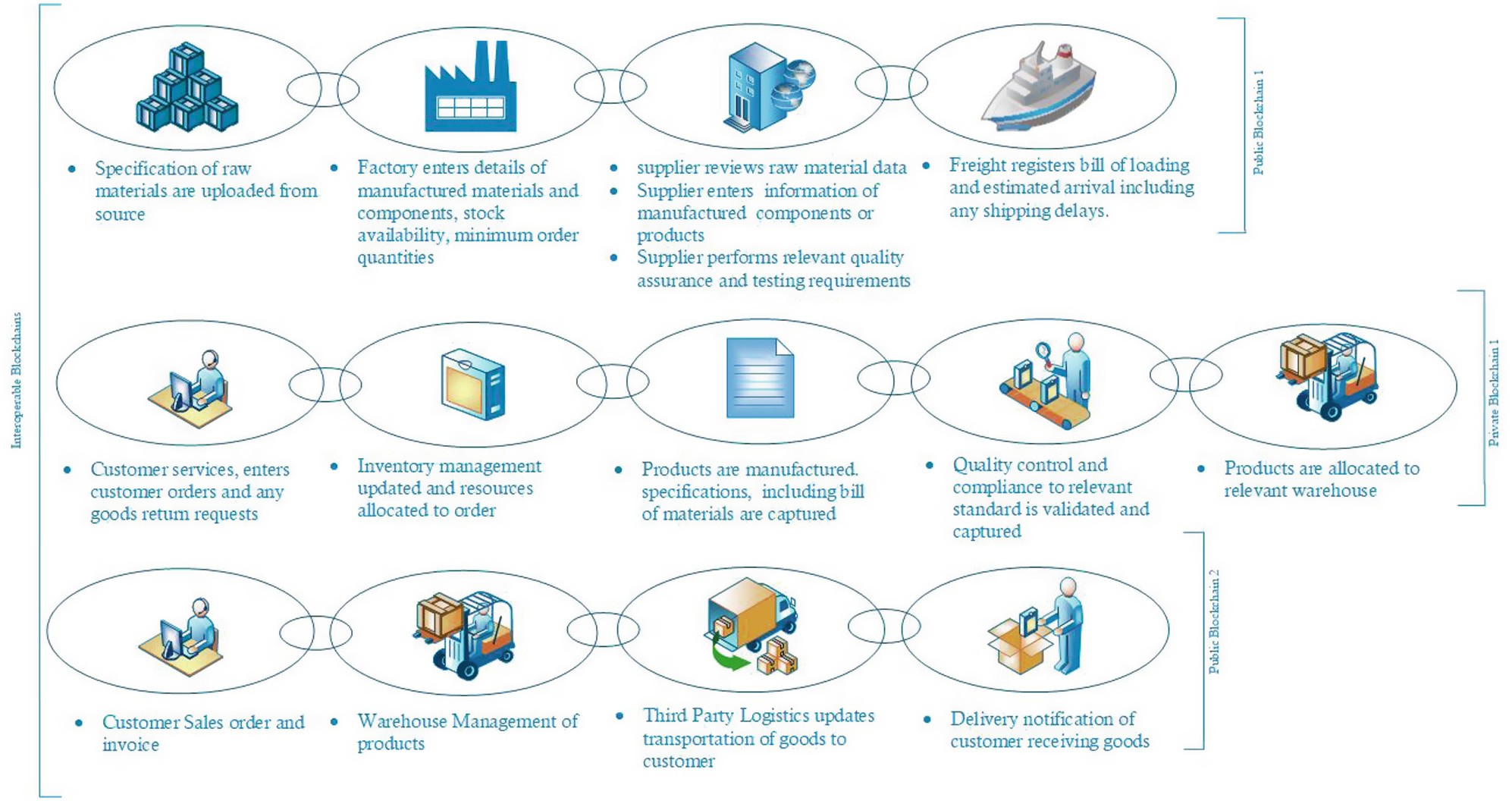

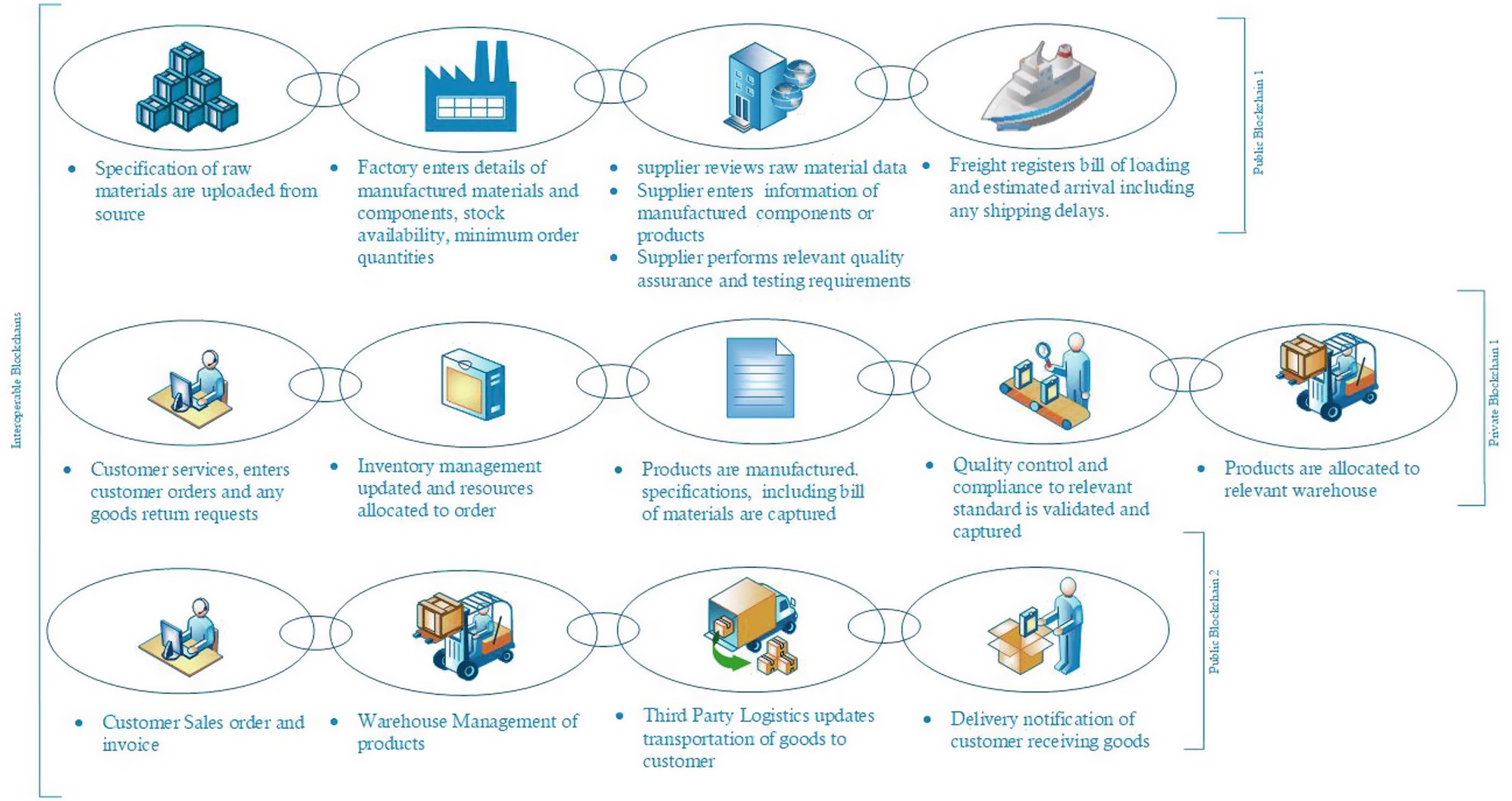

The supply chain management involves many internal and external stakeholders which makes Blockchain suitable as it can accept inputs from different parties. The proposed model is for organisations to develop Public and Private Blockchains which are also interoperable. In addition to this, organisations need to ensure governance and business standards are in place in a virtual community. The segregation of data records and their hash value in different ledgers was also proposed [7] in order to protect the personal data and privacy of users.

The first Blockchain proposed in Fig. 1 is “Public Blockchain 1”, The Blockchain looks at the procurement from suppliers. Given this Blockchain is public it allows for external stakeholders to enter information such as the sources of the raw materials, the factory of where the components are being produced, the stock availability, minimum order quantities. The supplier of the produced components can also enter any of their purchase order details and the quality assurance and testing which has been performed. Finally, the freight forwarder enters details of the goods being picked up and details of expected timeframes of delivery and any delays experienced.

Fig. 1. Overview of proposed concept

The second interoperable Blockchain proposed is “Private Blockchain 1”, this Blockchain contains customer orders, inventory and specific product specifications such as the bill of materials required. Once the components or products are received from the supplier, they are entered and the allocation of products to a warehouse is captured. Quality control and compliance records are also added to the Blockchain.

The third Blockchain is a public Blockchain and contains, customer orders, warehouse management such as stock availability, distribution management of the transportation from the warehouse to the customer and delivery confirmation. The use of interoperable public and private Blockchain technology allows for a more trans- parent supply chain of goods or services. Each Block in the chain provides stakeholders ability to control information through secure, auditable, and immutable record.

The model proposed captures all parties involved in the supply chain management and ensures there are no missed transactions, or errors, or even a transaction is not done with the consent of all the stakeholders involved. All data in the supply chain network is captured on the Blockchain and is available to participants who have the correct authentication. The most crucial area where the Blockchain helps in is the guarantee of validity and accountability of a transaction by the relevant stakeholder. The three Blockchains allow for interoperability hence giving the business the ability to view the entire supply chain. It is up to the discretion of the organisation to allow consumers to view further then the “Public Blockchain 2”.

Based on review of the literature and the development of both bitcoin and Blockchain we apply the conceptual TAM model and derived Table 1. This table identifies the major factors that influence users of Blockchain PE and PEU. Most Blockchain applications are still in the development stage, and the characteristics of their PEU would differ depending on the product and application.

Table 1. TAM factors applied to Blockchain

| Perceived ease of use (PEU) | Perceived usefulness (PU) |

| Variable depending on application use | Reduce cost |

| Eliminate intermediaries | |

| Simplify business process | |

| High transaction security | |

| Increase trust | |

| Scalable |

The general idea for the existence of Blockchain is to simplify processes, reduce costs and eliminate intermediaries. One of the earliest attempts to do this was use of Blockchain to replace the currently centralized domain name system (DNS) [38].

Case Study – Australian Electrical Manufacturer

The case study is an example application scenario where specific details of the supply chain are explained to better clarify the potential for the proposed concept.

Australia’s leading electrical manufacture and distributor (AEM) has a wide range of brand portfolios targeting the roadway & infrastructure, commercial & industrial, consumer and retail market segment of the electrical industry. In a very competitive market and with the availability of cheap imports easily accessible via the internet, organisations need to continuously streamline and optimise their processes to remain competitive. AEM is vertically integrated, incorporating, engineering and design, research, manufacturing, global sourcing, importation and distribution. This allows AEM to develop new products and produce prototypes for customer approval. It also gives the flexibility to design variations and bespoke designs from a single unit to thousands of units. The supply chain consists of three warehouses, one located on the west coast of Australia and the other two on the east coast.

The electrical industry has intensely changed in the past 5 years due to the rapid advancements in technology. The lifespan of products has also changed to as low as 6 months, hence the speed to market is crucial. The supply of products is an intricate part of the business as it consists of multiple segments of the electrical industry, currently the flow of information in the supply chain is siloed where information can’t be easily shared and accessed. A technique used to try and improve the flow of inventory between the raw material and component suppliers to the manufacturer is a contract to commit. This guarantees payment and provides comfort for international suppliers to purchase the materials required based on the contract. The technique is also used to reduce delays the supplier may face in sourcing raw materials. The Roadway business segment involves luminaries for roads, tunnels and bridges. It is run by contractual agreements with customers that detail what products are required and when. These product demands are added to the forecast based on these agreements. At times, there may be delays in obtaining goods from suppliers however this information is not always relayed back to all stakeholder’s due to the intricacies of the supply chain.

ABC analysis also known as selective inventory control is a term used to define inventory into categorisations. The grouping in to three or more categories (A, B and

C) is carried out to manage the different stocked keeping units (SKU’s) that are not all in equal value or customer order frequency. Special consideration is taken for new and critical items such as components required to manufacture make to order products. There are two types of purchasing instruments which are used, customer demand driven purchasing and system forecasting. Forecasting is based on policies setup in the enterprise resource planning (ERP) system and relies on historical sales; these items may not necessarily have customer demand but are required to meet customer’s availability expectations. Customer demand driven orders (Indent Stock) don’t consider historical sales, however, the purchasing team do need to contemplate lead times and the suppliers’ minimum order quantity. These are generally not considered when a sales representative makes a sale to a customer. The demand unpredictability causes series risks with procurement and can lead to a rapid increase of obsolete stock.

Material Requirements Planning (MRP) is a planning and inventory control system which is contained in the enterprise resource planning (ERP) system. Its aim is to safeguard adequate inventory levels are kept and assure that the required materials needed to manufacture goods are available when needed. Consideration also needs to be taken if stock is ordered and it does not meet the minimum requirement; does the organisation proceed with the sale and purchase excess stock and risk having an

overstock which results to additional overheads. The retail segment of the business is also based on projects and project plans of what and when the products are required. As these products are generally one of the last parts that are installed in a project there is a risk of miscommunication in the business, for instance if a project falls behind plan or over budget the product requirements may change and the sales representative does not inform the planning department, products which are no longer required could end up in the warehouse and take up valuable resources and space.

The category team manage product categories and their performance, they set the objectives and targets for the category and devise an overall strategy and specific tactics to achieve the required sales. The team oversees new products for 12 months from the date the product is received. Overall category, forecasting and marketing teams advise the purchasing team of what the business is expecting to sell.

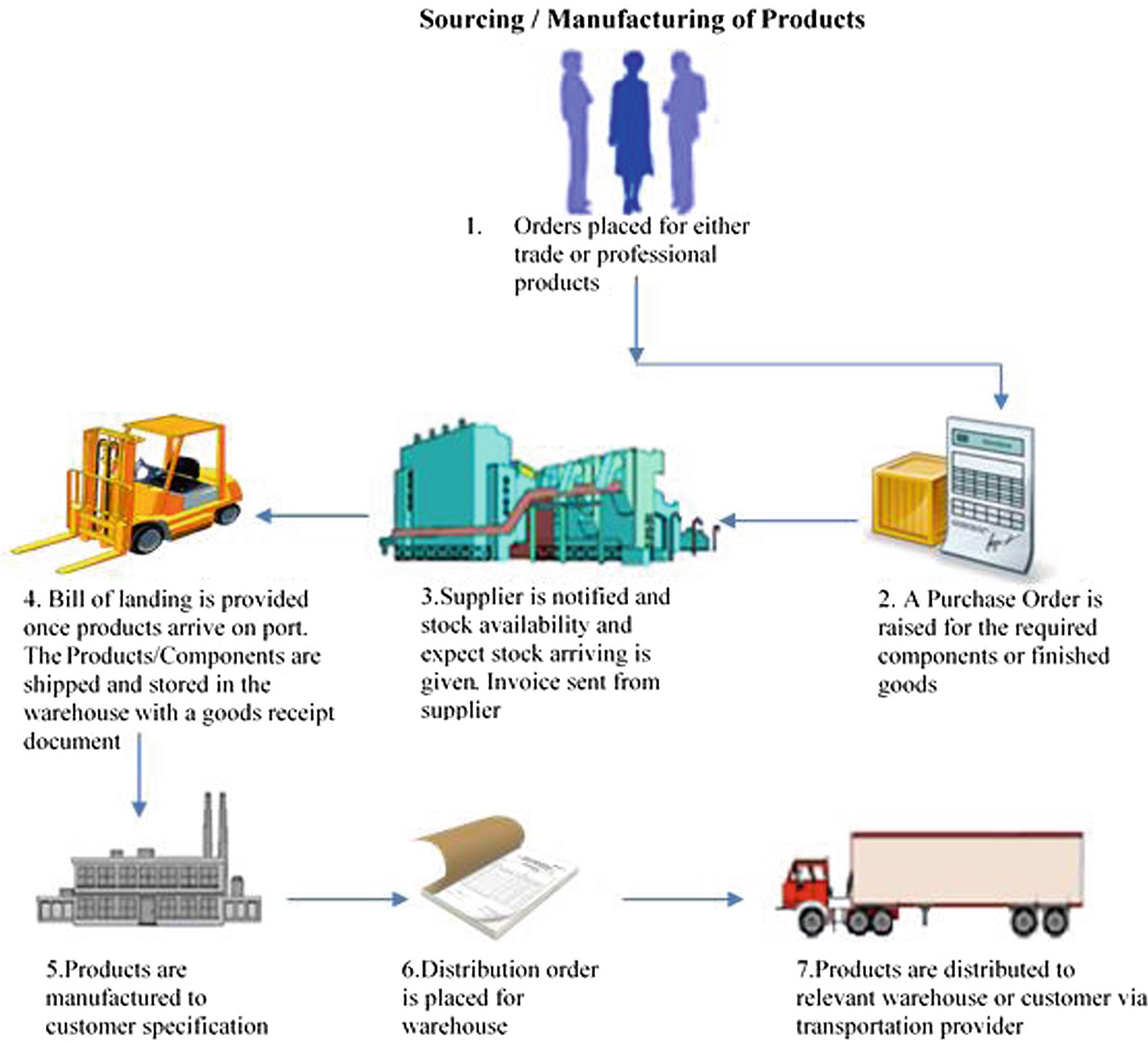

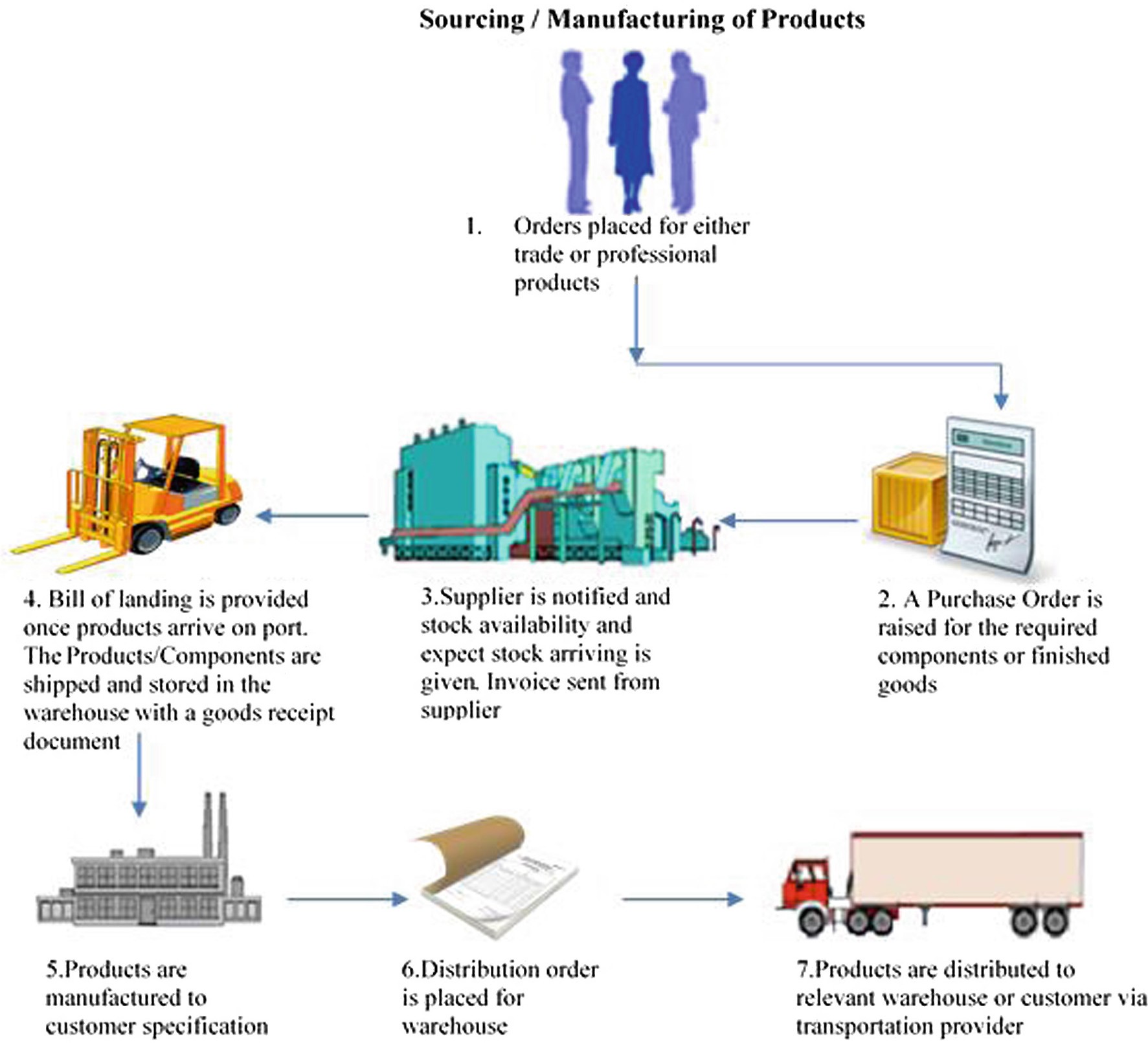

Generally, the top 80% of customer required products are stored in the warehouse and 20% of the products (SKU) is 80% of the business [39]. At times when products ordered by a customer cannot be located in the one warehouse a distribution order is completed to relocate the required product to the one distribution warehouse. However, if a product is not located in either warehouse an inventory sourcing purchase order needs to be raised to the supplier. A common issue faced is whereby sales represen- tatives may not know the lead times required or are reluctant to tell the customer that there is a 10-week lead time and then pressure is put back on to the purchasing and supply chain teams to ensure the product can be sourced with minimal amount of time. Also, if a customer order is cancelled by the sales representative and the distribution order is not this causes the purchasing team to have no visibility of the cancelled order and the purchases may still proceed. This is an issue where the chain of events occurring in Fig. 2 are not connected and transparency of information is not present to all stakeholders.

It is generally easy for the organisation to place an order with the suppliers but extremely difficult once a purchase order has been approved and sent. The organisation is simply locked in at that stage and committed to the purchase of the goods. It is also possible for the purchasing team to miss any cancelled orders made on the distribution orders. Traceability and transparency are the most important in logistics.

The safety stock applicable to certain products will only cover a small amount additional orders, however it will not cover any spikes in sales; therefore, communi- cation between marketing, sales, supply chain and procurement team is crucial. At times the marketing team may run promotions on certain products and this may cause an influx in orders which quickly depletes the safety stock and customer orders are held up in backorder. The previously forecasted purchase order which may be expected to arrive may only cover the backorders and not any new orders. This creates a cycle of where the purchasing team try to catch up to customer orders. It is important to calculate it accurately, because having too much stock will increase the inventory costs and having too little will cause stockouts as inventory will be exhausted. There is a standard calculation which is used for safety stock, however the lead time is also considered and hence the higher the lead time than the higher the safety stock is. A key system issues faced in such an environment is when a product is deemed as “I” (Indent Stock) and has a safety stock. This should flag for an alarm to sound and no safety stock should be purchased. It is ideal to be running a lean supply chain with the aim to

Fig. 2. The sourcing and manufacturing of products

balance customer service goals and the inventory costs. The transparency and accuracy of information is vital to achieve this and ensure no wastage.

The proposed model of using public and private Blockchains optimises the man- ufactures business transactions and trading relationships with its suppliers both locally and globally. A Blockchain on the supply chain can give clear visibility to all parties and allow for decisions and actions to be made quicker. Compared with conventional databases, using public Blockchain costs more to add records. Calculations and experiments have been performed in literature and show that the cost for business process execution on a Blockchain can have a two fold increase than a traditional database on a cloud platform [40]. However, data becomes globally replicated and the Blockchain ecosystem will retain this data indefinitely as long as the Blockchain exists, at no additional cost [41]. The three interoperable Blockchains create a chain of events or transactions that occur between the end customer, manufacturer, and supplier. A Blockchain that can directly interact with the sales team within the business and the suppliers will provide assurance that performance and correct communication is achieved in obtaining stock for the customer when needed. By using the proposed “Public Blockchain 1” the manufacture will have traceability from the source of the raw materials through to the components and the quality assurance and checks which have been performed. In addition to this the supply of goods can be tracked through

with the freight provider. This transparent level of information provides a link between the manufacture and the external stakeholders involved all recording and sharing information that can be assigned further down the supply chain. This Blockchain solves the issue of not knowing when a purchase order of goods is arriving and the properties and details of the products that it contains. The use of “Private Blockchain 1” is within the organisation and provides links between the customer order and the final manu- factured goods for the customer. This Blockchain creates visibility on where products can be found in a warehouse, the quality control performed and if the products have been allocated to a customer order. This traceability also helps with the inventory management in ensuring there is adequate stock available for an order to be made. The third Blockchain proposed “Public Blockchain 2” is public and links the customer order through to the warehouse and transportation provider. The record keeping and linking of this chain ensures customers receive the order in full, on time and from the correct warehouse. Due to the absence of other available alternatives to solve the communications problem in the supply chain, Blockchain is likely to become an attractive and cost-effective option [23]. The use of the three interoperable Blockchains within the business also provides transparency for the sales representatives who will have visibility on relevant information such as the components being used, the supplier its coming from, the lead times required and stock availability.

Conclusion

The general spread of the Internet of Things (IoT) makes the idea of integrating Blockchains in existing transaction supply chains the more significant. It will facilitate the creation of new supply chains to support the spread of sensor technologies. Blockchain can enable various upstream and downstream parties in supply chain to verify the authenticity of a Block of items. For this to happen, the paper describes several opportunities where Blockchain can integrate its use in the flow of the supply chain. This research develops a conceptual model for the adoption and use of Block- chain technology in supply chain, while utilizing the influential factors from TAM. The supply chain demonstrated in the case study is a large part of an organisation and it involves internal and external stakeholders. It is possible that not all parties will par- ticipate in this technology, however, the idea is compelling as it enables interoperable public and private deployment of Blockchains in supply chain management. This will allow organisations to leverage a variety of Blockchain applications and solutions to help in the transparency, traceability and authenticity of information. This technology does not necessarily need to be applied to an entire supply chain, it may be added to certain parts to the supply chain management such as the “Public Blockchain 2” used for inventory management. This can improve the record keeping, traceability and accuracy within the manufacturing organisation.

Recently, IBM is experimenting with a system called Adept that permits exchange among billions of interconnected devices using a Blockchain approach. It has devel- oped a semi-autonomous device based on Internet of Things concept integrated with the Blockchain with the collaboration of Samsung. This device is a kind of intelligent washing machine which can manage its own consumables supply like ordering

detergent as required, perform its own self-service and maintenance, and even optimize its environment by negotiating with other peer devices in the home or outside. Tech- nology leaders believe that Blockchain will do for transactions what the internet did for information. One potential issue that needs to be considered in the use of Blockchain is that if the first Block in the chain the geneis is created without a trustworthy source and each additional Block thereafter is also agreed on by the Blockchain stakeholders then theoretically this chain of events can be unreliable. Compared to conventional cen- tralised databases and computational platforms, Blockchains can reduce some counter- party and operational risks by providing neutral ground between organisations [42].

In this paper the authors reviewed some of the main characteristics of Blockchain and discussed the benefits and limits. The focus of the paper was placed on the application within the supply chain in an electrical manufacturing business and the influential variables of TAM. A hypothetical vision for a Blockchain supply chain was proposed and an example scenario of the supply chain was explained. The authors fully understand the technical and political challenges ahead. For future studies we will invite domain experts to evaluate the proposed model in a real-world application. There is still much that is unknown about the Blockchain-based systems [42]. Further research is required to improve our knowledge on how to create Blockchain-based systems that work and creating Blockchain-based systems that work as required.

References

- Ali, M.M., Babai, M.Z., Boylan, J.E., Syntetos, A.A.: Supply chain forecasting when information is not shared. Eur. J. Oper. Res. 260(3), 984–994 (2017)

- Lemieux, V.L.: Trusting records: is Blockchain technology the answer? Rec. Manag. J. 26

(2), 110–139 (2016)

- Luther, W.J.: Bitcoin and the future of digital payments. Independent Rev. 20(3), 397–404 (2016)

- Xu, X., et al.: The blockchain as a software connector. In: Proceedings – 2016 13th Working IEEE/IFIP Conference on Software Architecture, WICSA 2016 (2016)

- Nakamoto, S., Bitcoin: A Peer-to-Peer Electronic Cash System (2009)

- Swan, M.: Blockchain temporality: smart contract time specifiability with blocktime. In: Alferes, J.J.J., Bertossi, L., Governatori, G., Fodor, P., Roman, D. (eds.) RuleML 2016. LNCS, vol. 9718, pp. 184–196. Springer, Cham (2016). https://doi.org/10.1007/978-3-319- 42019-6_12

- Zyskind, G., Nathan, O., Pentland, A.: Enigma: Decentralized computation platform with guaranteed privacy. arXiv preprint arXiv:1506.03471 (2015)

- Ølnes, S.: Beyond bitcoin enabling smart government using blockchain technology. In: Scholl, H.J., et al. (eds.) EGOVIS 2016. LNCS, vol. 9820, pp. 253–264. Springer, Cham (2016). https://doi.org/10.1007/978-3-319-44421-5_20

- Dierksmeier, C., Seele, P.: Cryptocurrencies and business ethics. J. Bus. Ethics 152, 1–14 (2016)

- Vukolić, M.: The quest for scalable blockchain fabric: Proof-of-work vs. BFT replication. In:

Camenisch, J., Kesdoğan, D. (eds.) iNetSec 2015, vol. 9591, pp. 112–125. Springer, Heidelberg (2016). https://doi.org/10.1007/978-3-319-39028-4_9

- Yue, X., Wang, H., Jin, D., Li, M., Jiang, W.: Healthcare data gateways: found healthcare intelligence on blockchain with novel privacy risk control. J. Med. Syst. 40(10), 218 (2016)

- Yuan, Y., Wang, F.Y.: Blockchain: the state of the art and future trends. Zidonghua Xuebao/Acta Autom. Sinica 42(4), 481–494 (2016)

- Christidis, K., Devetsikiotis, M.: Blockchains and smart contracts for the internet of things. IEEE Access 4, 2292–2303 (2016)

- Herlihy, M., Moir, M.: Enhancing accountability and trust in distributed ledgers. arXiv preprint arXiv:1606.07490 (2016)

- Zhao, J.L., Fan, S., Yan, J.: Overview of business innovations and research opportunities in blockchain and introduction to the special issue. Financ. Innov. 2, 28 (2016)

- Kar, I.: Estonian citizens will soon have the world’s most hack-proof health-care records, Quartz. https://qz.com/628889/this-eastern-european-country-is-moving-its-health-records- to-the-blockchain. Accessed 15 July 2017

- Council, B.B.: Russia’s Central Bank to Develop National Cryptocurrency. http://brics-info. org/. Accessed 06 June 2017

- Nott, G.: ANZ and Westpac trial blockchain for bank guarantees, (CIO). https://www.cio. com.au/article/621585/anz-westpac-trial-blockchain-bank-guarantees. Accessed 10 July 2017

- Back, A., et al.: Enabling blockchain innovations with pegged sidechains. https:// blockstream.com/sidechains.pdf. Accessed 20 July 2017

- Chuen, D.L.K., Deng, R.H. (eds.): Handbook of Blockchain, Digital Finance, & Inclusion, Volume 2: ChinaTech, Mobile Security, & Distributed Ledger. Academic Press, Cambridge (2017)

- PWC, Blockchain – an opportunity for energy producers and consumers? (2016)

- Dirkmaat, O.: Beyond the Bitcoin Hype: Limitations of Bitcoin and Blockchain Technology. https://trends.ufm.edu/en/article/beyond-bitcoin. Accessed 16 Sept 2017

- Kan, L., Wei, Y., Muhammad, A.H., Siyuan, W., Linchao, G., Kai, H.: A multiple blockchains architecture on inter-blockchain communication. In: 2018 IEEE International Conference on Software Quality, Reliability and Security Companion (QRS-C), pp. 139–

145. IEEE, July 2018

- Wood, G.: Polkadot: Vision for heterogeneous multi-chain framework. White Paper (2016)

- Ding, D., Duan, T., Jia, L., Li, K., Li, Z., Sun, Y.: InterChain: A Framework to Support Blockchain Interoperability (2018)

- Greenspan, G.: MultiChain private blockchain—White paper. http://www.multichain.com/ download/MultiChain-White-Paper.pdf. Accessed 05 Aug 2018

- Andoni, M., et al.: Blockchain technology in the energy sector: a systematic review of challenges and opportunities. Renew. Sustain. Energy Rev. 100, 143–174 (2019)

- Haq, I., Monfared, R., Harrison, R., Lee, L., West, A.: A new vision for the automation systems engineering for automotive powertrain assembly. Int. J. Comput. Integr. Manuf. 23 (4), 308–324 (2010)

- Korpela, K., Hallikas, J., Dahlberg, T.: Digital supply chain transformation toward blockchain integration. In: Proceedings of the 50th Hawaii International Conference on System Sciences, January 2017

- Apte, S., Petrovsky, N.: Will blockchain technology revolutionize excipient supply chain management? J. Excipients Food Chem. 7(3), 910 (2016)

- Kietzman, S.: What is a Supply Chain? http://www.wisegeek.org/what-is-a-supply-chain. htm. Accessed 08 Sept 2017

- Casado-Vara, R., Prieto, J., De la Prieta, F., Corchado, J.M.: How blockchain improves the supply chain: case study alimentary supply chain. Procedia Comput. Sci. 134, 393–398 (2018)

- Davis, F.D.: A technology acceptance model for empirically testing new end-user information systems: theory and results. Doctoral dissertation, MIT (1985)

- Davis, F.D.: Perceived usefulness, perceived ease of use, and user acceptance of information technology. MIS Q. 13, 319–340 (1989)

- Chen, J., Park, Y., Putzer, G.J.: An examination of the components that increase acceptance of smartphones among healthcare professionals. Electron. J. Health Inform. 5(2), 16 (2010)

- Abdalla, I.: Evaluating effectiveness of e-blackboard system using TAM framework: a structural analysis approach. Aace J. 15(3), 279–287 (2007)

- Liu, I.-F., Chen, M.C., Sun, Y.S., Wible, D., Kuo, C.-H.: Extending the TAM model to explore the factors that affect Intention to Use an Online Learning Community. Comput. Educ. 54(2), 600–610 (2010)

- Fotiou, N., Polyzos, G.C.: Decentralized name-based security for content distribution using blockchains. In: 2016 IEEE Conference on Computer Communications Workshops (INFOCOM WKSHPS). IEEE (2016)

- Coyle, J.J., Langley, C.J., Novack, R.A., Gibson, B.: Supply Chain Management: A Logistics Perspective. Cengage Learning, Boston (2012)

- Rimba, P., Tran, A.B., Weber, I., Staples, M., Ponomarev, A., Xu, X.: Comparing blockchain and cloud services for business process execution. In: Proceedings – 2017 IEEE International Conference on Software Architecture, ICSA 2017 (2017)

- Staples, M., et al.: Risks and opportunities for systems using blockchain and smart contracts. Data61. CSIRO, Sydney (2017)

- Cosmos. https://cosmos.network/docs/resources/whitepaper.html. Accessed 05 July 2017

Questions:

1-What are the expected benefits of Public Blockchain 1, private Blockchain 1, and Public Blockchain 2 in the proposed model?

2- What are the main challenges facing Supply chain management highlighted in this case study?

3- In general, what are the technology adoption barriers?

4- explain how Blockchain can enable various upstream and downstream parties in supply chain to verify the authenticity of a Block of items.

5- Discuss the main pros and cons of the proposed solution?

Questions: three marks each question.

1-What are the expected benefits of Public Blockchain 1, private Blockchain 1, and Public Blockchain 2 in the proposed model?

2- What are the main challenges facing Supply chain management highlighted in this case study?

3- In general, what are the technology adoption barriers?

4- explain how Blockchain can enable various upstream and downstream parties in supply chain to verify the authenticity of a Block of items.

5- Discuss the main pros and cons of the proposed solution?

Blockchain in Supply Chain Management: Australian Manufacturer Case Study

![]()

![]()

![]() Elias Abou Maroun1(&) , Jay Daniel2 , Didar Zowghi1 , and Amir Talaei-Khoei3

Elias Abou Maroun1(&) , Jay Daniel2 , Didar Zowghi1 , and Amir Talaei-Khoei3

1 Faculty of Engineering and IT, University of Technology Sydney, Sydney, Australia

Elias.AbouMaroun@student.uts.edu.au, Didar.Zowghi@uts.edu.au

2 Derby Business School, University of Derby, Derby, UK

3 Department of Information Systems, Ansari College of Business, University of Nevada, Reno, NV, USA

Abstract. The recent explosion of interest around Blockchain and capabilities of this technology to track all types of transaction more transparently and securely motivate us to explore the possibilities Blockchain offers across the supply chain. This paper examines whether Blockchain makes a good fit for use in an Australian manufacturer supply chain. To address this, the research uses Technology Acceptance Model (TAM) as a framework from the literature. Blockchain allows us to have permissioned or permission-less distributed led- gers where stakeholders can interact with each other. It details how Blockchain works and the mechanism of hash algorithms which allows for greater security of information. It also focuses on the supply chain management and looks at the intricacies/complexity of a manufacturers supply chain. We present a review of the processes in place of an electrical manufacturer and the problems faced in the supply chain. A model is proposed in using public and private Blockchains to overcome these issues. The proposed solution has the potential to bring greater transparency, validity across the supply chain, and improvement of communication between stakeholders involved. We also point out some potential issues that should be considered if adopting Blockchain.

Keywords: Manufacturing supply chain management Blockchain Distributed ledger

· ·

Introduction

The amount of data being created and collected is growing at an exponential rate. This growth is primarily due to technology advances in devices which are known as the ‘Internet of Things’ (IOT) and the significance of computer power and availability of storage resources. Data is evolving and becoming part of everyday human activity, from product goods being sourced, product manufacturing and delivery of products to

© Springer Nature Switzerland AG 2019

H.-P. Lam and S. Mistry (Eds.): ASSRI 2018, LNBIP 367, pp. 93–107, 2019.

https://doi.org/10.1007/978-3-030-32242-7_8

consumers. The increase in data has provided opportunity for new approaches and techniques to create, store, analyse and obtain useful insight from the supply chain.

Supply chains are known to be large, complex and often unpredictable as they include four essential functions: sales, distribution, production, and procurement. They represent all the links that are involved in the sourcing of raw materials, manufacturing of goods, and the distribution of a finished product to the end consumer. Operational management of supply chains requires methods and tools to enable organisations to better understand how unexpected disruptions occur and what impacts they will have on the flow of goods to customer demand. Supply chain visibility provides opportu- nities for managers not only to plan efficiently but also to react appropriately to the accurate information [1].

Supply chains can span from over hundreds of stages and multiple geographical locations which makes it complex to trace events in the supply chain and investigate any issues. To date, customers have no reliable way to validate the true value and authenticity of a product purchased due to the lack of transparency, tracking, recording and sharing of information. The lack of transparency causes an absence of information from being shared about the manufacturing process of goods, assembly, delivery and certification of materials used that might pose risks and issues in the supply chain. This also poses a risk to fraud occurring in the supply chain such as counterfeiting of products, and the accountability of any illicit activities that may occur. Generally, questions are raised when manufacturing goods such as where are these components coming from? Do they meet the expected standards and are they safe?

Supply chains suffer from inefficiencies in the recording of assets such as pallets, trailers and containers that are continuously moving between supply chain nodes. There are issues in the tracking of purchase orders, receipts, shipment notifications and other trade related documents. The lack of assigning or verification of certain properties of the physical products or the linking of goods to serial numbers, bar codes or digital tags like radio frequency identification (RFID). Current Supply chain systems hold key data relating to each stage of the supply chain, people working in different stages must use the same system to update or complete the data of the process. This localized system typically an enterprise resource system (ERP) are comprised of localized possession of the company data and does not hold the complete stages of the supply chain. The objective is to bridge the gap between the different stages of the supply chain using Blockchain for supply chain management.

The Blockchain technology allows for data to be written in files called Blocks. The Blockchain technology can record transactions of almost any type based on certain conditions that are agreed on by stakeholder which can solve record keeping issues, however, computer professionals remain skeptical about relying on this technology for complex and long-term transactions management. They remain unsure about the preservation ability of the system for trusted digital records. Lemieux [2] and [3] identify threats and vulnerability of Blockchain as control base threats (Control of Blockchain, and Control of record creation outside of Blockchain), attack base threats (Man-in-the-middle attack, SYN Flood attack, Sybil attack, and Audit server attack), system base threats (Timing errors, and Preservation of original records), and process base threats (Change of bit rot to encryption, Collision of hashes, and encryption code Breakage). The Blockchain enables different organisations to collaborate and validate

entries in the Blockchain hence giving stakeholders visibility of the overall activities taking place. This paper proposes using Blockchain technology to enable various upstream and downstream parties in supply chain to verify the authenticity of each individual Block and provide transparency across different stages of the supply chain. Various parties in the supply chain first provide input and agree on the content of a Block. Once in place, the Blockchain will include a set of constraints which cannot be violated by any Block.

An Australian electrical manufacturer (AEM) has been chosen to address the issues of traceability, transparency and inefficiencies which are common in supply chain management. The supply chain chosen is also common among the fast-moving con- sumer goods industry. The remainder of this paper is organised as follows: Sect. 2 the related work is reviewed. The proposed model and case study are discussed in Sects. 3 and 4, respectively. Finally, Sect. 5 provides discussion, conclusion and future work in this area.

Literature Review

Recently, more and more applications are being created based on Blockchain tech- nology [4]. Initially, the Blockchain technology was the key technique behind Bitcoin [5]. Bitcoin is a popular form of digital cryptocurrency which was developed in 2008 by “Satoshi Nakamoto”. The technology underlying Bitcoin is named Blockchain which acts as the payments layer for Internet. This new form of general computational substrate is a mechanism for updating truth states in distributed computer networks [6]. A recent survey has divided Blockchain-inspired technologies into two [7] fully decentralized permission-less ledgers, (e.g., Bitcoin, Ethereum), and semi-centralized permissioned ledgers (e.g. Ripple). These ledgers are known as ‘distributed ledgers’. Lack of studies in the applicability of Blockchain technology motivated researchers to find the possibilities of this technology in other areas. Ølnes [8] investigated the possible application of this technology in electronic governments. To this end, a case of storing academic certificates on the Blockchain was presented to highlight the inno- vation potential of the new technology for storing and securing vital information. He concluded that although Blockchain is a promising technology for validating many types of persistent documents, still there is a long way to implement this technology in public sector. Nevertheless, the implications and limitations of using such technologies as a software connector had been elaborated as well. Dierksmeier and Seele [9] pro- vided rationale to address the impact of “Blockchain technology” on the nature of financial transactions from a business ethics perspective. They combined different business and society levels such as micro, meso, and macro to propose a framework for assessing current status of cryptocurrencies ethical debates.

-

- Blockchain

Several studies have attempted to find the performance and impacts of Blockchain in comparison with other systems. Focusing on their scalability limits. Vukolić [10] made a comparison between proof-of-work (PoW)-based Blockchains to those based on

Byzantine fault-tolerant (BFT) state machine. To tackle these limits, they reviewed recent proposed solutions developed for the ultimate Blockchain fabric. Based on the experience in several Blockchain projects, Xu, Pautasso [4] studied the architectural decisions in a system. In the situation whether to employ a decentralized Blockchain as opposed to other software solutions such as a traditional shared data storage.

Lemieux [2] studied to what extent Blockchain technology creates trustworthy digital records by applying a risk-based assessment method to evaluate the imple- mentation of Blockchain technology in land registry system. The results indicated that although Blockchain technology can be used to address issues associated with infor- mation integrity in the present and near term [2], the reliability of information and maintaining long-term preservation could not be guaranteed. In 2016, a study was conducted on interdisciplinary fields of Blockchain and the healthcare system to pre- vent data sharing and improve patients’ privacy by enabling them to own, control and share their own data easily and securely. In this regard, an App named Healthcare Data Gateway (HGD) that was designed based on Blockchain architecture has been devel- oped by Yue, Wang [11] with the capability to organize and categorize all kinds of personal healthcare data and secure Multi-Party Computing.

The solution that Blockchain proposes is the use of a timestamp server that takes the hash of a Block of items, timestamps it, and widely publishes the hash [12]. This involves using hash algorithms to find a specific value. The Block is only accepted by users if all transactions in it are valid and the Bitcoins have not been spent previously [12]. Users show their acceptance by using the newly found hash in the “previous hash” section of the next Block they attempt to generate. This adds a new Block to the chain (the Block chain or transaction log). The chain thus contains the entire history of all transactions that have been carried out in the network [12]. The first Block of a Blockchain is called the genesis and has no parent as each Block on the Blockchain is referenced or identified by its hash [13]. A Blocks hash is typically a one-way hashing function used that maps an input to an output. There are different types of hash algorithms which may be used. For example, applying the SHA-1 hash algorithm function to a string “hello Blockchain” will produce the following hash value “bdb9814fb8929bd976a8ba1a4e037992ca7111e0”.

Applying a hash function to a string will return a new string and if that string remains the same, the same hash will be produced. Data integrity is optimal as one can verify their hash with a hash key that has been given when downloading a file. This is done by comparing both hash keys as this ensures the file has not been tampered with and every byte of data is exactly the same. The Blockchain, also known as the con- sensus protocol [14], serves as a public or private ledger for any transactions, and every user is able to connect to the network and send transactions to the Blockchain, verify transactions and create new Blocks. It is a data structure which is used to ensure secure and tamper proof distributed ledgers. Each Blockchain is made up of Blocks which are linked to a previous Block and contain exclusive data and a timestamp.

To form a Blockchain, sequences of bits encrypted as a Block are stored by net- worked computers (nodes) within a system and are chained together. The veracity of new Blockchain links are established by a decentralized mining process. Before new links are formally added to the Blockchain, a meticulous mathematical hash is derived by competing mining computers to verify their content [12]. When a bitcoin is

transferred to the next user, it gets digitally signed with a hash value denoting the precedent transaction and the public key of the next owner. The hash is defined as a chain of signatures. These can be verified by the payee to authenticate the chain of ownership [12]. To become part of the peer-to-peer network, one needs to have a client software that runs on either an own device or on a cloud service [12]. Nodes in the network only accept the first authenticated transaction and reject any subsequent attempts to make any further transactions to stop malicious users from rewriting their history.

-

- Applications of Blockchain

Most current cloud-based applications rely on a single trusted controlling organisation that manages the network, storage and compute. This approach may be desirable for some applications however in some cases, a decentralized and distributed approach is better suited. For example, Walmart, the world’s largest retailer is conducting pilot tests for worldwide supply chain food traceability [15]. The increasing development of the digital economy, the internet of things (IOT) and the growing use of sensors providing information in supply chains is providing Blockchain leverage to streamline and create an efficient supply chain track and trace management system. There are examples of Blockchain technology going beyond the realm of currencies and banking and evolving into industries such as real estate, for land registry systems, digital healthcare record systems [16] and government identification and registry systems [13]. Many businesses have already begun accepting Bitcoin in their payments including PayPal, Apple, and Universal Air Travel Plan (UATP). In addition, firms such as Citi Corp, Goldman Sachs, Barclays, Overstock, and IBM started to pay attention to cryptocurrencies. Governments around the world are creating policies for cryptocurrency, including Brazil, Russia, India, China and South Africa (BRICS). The BRICS business council is also debating the possibility in creating a BRICS cryptocurrency as an alternative to other financial instruments Council [17]. USA has already deployed bitcoin technology for interbank payments and Australia has already began a trial for bank guarantees using Blockchain technology [18]. Interoperability challenges between bitcoin and other ledger assets between multiple Blockchains have been addressed by creating mechanisms such as Pegged Sidechains [19].

-

- Benefits and Limitations

Processing transactions over a distributed network without a central node functioning as a bank or clearing house reduces the cost of the transactions. Processing transactions using the Blockchain is less costly than the traditional approach Chuen and Deng [20]. However, the validation and verification of data comes with high hardware and energy costs [21]. The business of processing transactions tends to be highly concentrated and can be impacted with waiting for stakeholders executing their due diligence actions. With Blockchains, business transactions can be made to run in parallel potentially unleashing huge efficiency dividends e.g. businesses can unlock capital or value quickly rather than waiting for a transaction to be completed. The transactions volume handled by each payment processor can be increased manyfold but the added

coordination costs to overcome network effects need to be considered. The drawback of a single Blockchain is the exponential increase in the cost and time per Block and hence per transaction. However, there is an argument that the technology’s primary benefit is security and not efficiency Dirkmaat [22]. The ability to use multiple Blockchains to improve efficiency requires interoperability between different Block- chains. Blockchains need to be able interact with each other as a single Blockchain alone has limited performance [23]. Various studies such as [24], [25] and [26] have established a framework to exchange information between multiple Blockchains. Promising solutions also proposed to address this challenge by storing actual data in sidechains and operating the Blockchain as a control layer rather than as a storage layer [27]. The added benefits of using Blockchain is the reliability, where a single point of failure does not affect the whole operation of the network. The various works reviewed in this study show that Blockchain is a promising technology for a wide area of services.

-

- Supply Chain Management

Supply chain management comprises of a series of entities, including people, systems, knowledge and processes. In a large supply chain, it is difficult to have an overall picture of all transactions within the chains [28]. This data is typically stored in multiple systems which are only accessible by certain participants in the supply chain. Several papers [27, 29, 30] investigate how supply chain is becoming transformed through Blockchain technology. The digital supply chain integration is becoming increasingly dynamic. Blockchain technology is providing a major advance for supply chains in assisting the delivery of source, process and products. The adoption of Blockchain technology should make the process faster and make transactional records more robust and reliable [30]. Rather than limiting a supply chain to regions, the utilisation of Blockchain will make it possible to have global production chains that are visible remotely. This is in line with what Kietzman [31] observed the current unseen dimensions from the vast network of retailers, distributors, transporters, storage facil- ities, and suppliers that participate in design, production, delivery and sales will be transparent. Organisations will have a competitive advantage of open, transparent supply chains and sustainable manufacturing. Models have been created for tracking agriculture in the supply chain [32]. This new model demonstrates the concept of circular economy and eliminates many of the disadvantages of the supply chain such as the cost to exchange between different parties in the supply chain. An overview of the proposed application of Blockchain in supply chain is illustrated in our model.

-

- Technology Acceptance Model (TAM)

The technology acceptance model (TAM) was originally developed through a doctoral dissertation [33] and well cited in a MIS quarterly article [34]. Technology acceptance model is an information systems theory that models the decision-making process by which users may or may not adopt and implement new technology. There are two major considerations in TAM, perceived ease of use and perceived usefulness by the intended user.

Perceived ease of use (PEU) is defined by [34] as “the degree to which a person believes using the system will be free of effort.” The perceived usefulness (PU) is defined by [34], as “the extent to which a person believes that using a particular technology will enhance his/her job performance”. Technology acceptance models have been used to analyse the acceptance of technology in a variety of domains, from healthcare [35], a physician’s choice and acceptance of the use of smartphones. Technology acceptance model has also been helpful in education learning [36], where scholars have examined student and faculty adoption of online learning [37].

Proposed Model

The supply chain management involves many internal and external stakeholders which makes Blockchain suitable as it can accept inputs from different parties. The proposed model is for organisations to develop Public and Private Blockchains which are also interoperable. In addition to this, organisations need to ensure governance and business standards are in place in a virtual community. The segregation of data records and their hash value in different ledgers was also proposed [7] in order to protect the personal data and privacy of users.

The first Blockchain proposed in Fig. 1 is “Public Blockchain 1”, The Blockchain looks at the procurement from suppliers. Given this Blockchain is public it allows for external stakeholders to enter information such as the sources of the raw materials, the factory of where the components are being produced, the stock availability, minimum order quantities. The supplier of the produced components can also enter any of their purchase order details and the quality assurance and testing which has been performed. Finally, the freight forwarder enters details of the goods being picked up and details of expected timeframes of delivery and any delays experienced.

Fig. 1. Overview of proposed concept

The second interoperable Blockchain proposed is “Private Blockchain 1”, this Blockchain contains customer orders, inventory and specific product specifications such as the bill of materials required. Once the components or products are received from the supplier, they are entered and the allocation of products to a warehouse is captured. Quality control and compliance records are also added to the Blockchain.

The third Blockchain is a public Blockchain and contains, customer orders, warehouse management such as stock availability, distribution management of the transportation from the warehouse to the customer and delivery confirmation. The use of interoperable public and private Blockchain technology allows for a more trans- parent supply chain of goods or services. Each Block in the chain provides stakeholders ability to control information through secure, auditable, and immutable record.

The model proposed captures all parties involved in the supply chain management and ensures there are no missed transactions, or errors, or even a transaction is not done with the consent of all the stakeholders involved. All data in the supply chain network is captured on the Blockchain and is available to participants who have the correct authentication. The most crucial area where the Blockchain helps in is the guarantee of validity and accountability of a transaction by the relevant stakeholder. The three Blockchains allow for interoperability hence giving the business the ability to view the entire supply chain. It is up to the discretion of the organisation to allow consumers to view further then the “Public Blockchain 2”.

Based on review of the literature and the development of both bitcoin and Blockchain we apply the conceptual TAM model and derived Table 1. This table identifies the major factors that influence users of Blockchain PE and PEU. Most Blockchain applications are still in the development stage, and the characteristics of their PEU would differ depending on the product and application.

Table 1. TAM factors applied to Blockchain

| Perceived ease of use (PEU) | Perceived usefulness (PU) |

| Variable depending on application use | Reduce cost |

| Eliminate intermediaries | |

| Simplify business process | |

| High transaction security | |

| Increase trust | |

| Scalable |

The general idea for the existence of Blockchain is to simplify processes, reduce costs and eliminate intermediaries. One of the earliest attempts to do this was use of Blockchain to replace the currently centralized domain name system (DNS) [38].

Case Study – Australian Electrical Manufacturer

The case study is an example application scenario where specific details of the supply chain are explained to better clarify the potential for the proposed concept.

Australia’s leading electrical manufacture and distributor (AEM) has a wide range of brand portfolios targeting the roadway & infrastructure, commercial & industrial, consumer and retail market segment of the electrical industry. In a very competitive market and with the availability of cheap imports easily accessible via the internet, organisations need to continuously streamline and optimise their processes to remain competitive. AEM is vertically integrated, incorporating, engineering and design, research, manufacturing, global sourcing, importation and distribution. This allows AEM to develop new products and produce prototypes for customer approval. It also gives the flexibility to design variations and bespoke designs from a single unit to thousands of units. The supply chain consists of three warehouses, one located on the west coast of Australia and the other two on the east coast.

The electrical industry has intensely changed in the past 5 years due to the rapid advancements in technology. The lifespan of products has also changed to as low as 6 months, hence the speed to market is crucial. The supply of products is an intricate part of the business as it consists of multiple segments of the electrical industry, currently the flow of information in the supply chain is siloed where information can’t be easily shared and accessed. A technique used to try and improve the flow of inventory between the raw material and component suppliers to the manufacturer is a contract to commit. This guarantees payment and provides comfort for international suppliers to purchase the materials required based on the contract. The technique is also used to reduce delays the supplier may face in sourcing raw materials. The Roadway business segment involves luminaries for roads, tunnels and bridges. It is run by contractual agreements with customers that detail what products are required and when. These product demands are added to the forecast based on these agreements. At times, there may be delays in obtaining goods from suppliers however this information is not always relayed back to all stakeholder’s due to the intricacies of the supply chain.

ABC analysis also known as selective inventory control is a term used to define inventory into categorisations. The grouping in to three or more categories (A, B and

C) is carried out to manage the different stocked keeping units (SKU’s) that are not all in equal value or customer order frequency. Special consideration is taken for new and critical items such as components required to manufacture make to order products. There are two types of purchasing instruments which are used, customer demand driven purchasing and system forecasting. Forecasting is based on policies setup in the enterprise resource planning (ERP) system and relies on historical sales; these items may not necessarily have customer demand but are required to meet customer’s availability expectations. Customer demand driven orders (Indent Stock) don’t consider historical sales, however, the purchasing team do need to contemplate lead times and the suppliers’ minimum order quantity. These are generally not considered when a sales representative makes a sale to a customer. The demand unpredictability causes series risks with procurement and can lead to a rapid increase of obsolete stock.

Material Requirements Planning (MRP) is a planning and inventory control system which is contained in the enterprise resource planning (ERP) system. Its aim is to safeguard adequate inventory levels are kept and assure that the required materials needed to manufacture goods are available when needed. Consideration also needs to be taken if stock is ordered and it does not meet the minimum requirement; does the organisation proceed with the sale and purchase excess stock and risk having an

overstock which results to additional overheads. The retail segment of the business is also based on projects and project plans of what and when the products are required. As these products are generally one of the last parts that are installed in a project there is a risk of miscommunication in the business, for instance if a project falls behind plan or over budget the product requirements may change and the sales representative does not inform the planning department, products which are no longer required could end up in the warehouse and take up valuable resources and space.

The category team manage product categories and their performance, they set the objectives and targets for the category and devise an overall strategy and specific tactics to achieve the required sales. The team oversees new products for 12 months from the date the product is received. Overall category, forecasting and marketing teams advise the purchasing team of what the business is expecting to sell.

Generally, the top 80% of customer required products are stored in the warehouse and 20% of the products (SKU) is 80% of the business [39]. At times when products ordered by a customer cannot be located in the one warehouse a distribution order is completed to relocate the required product to the one distribution warehouse. However, if a product is not located in either warehouse an inventory sourcing purchase order needs to be raised to the supplier. A common issue faced is whereby sales represen- tatives may not know the lead times required or are reluctant to tell the customer that there is a 10-week lead time and then pressure is put back on to the purchasing and supply chain teams to ensure the product can be sourced with minimal amount of time. Also, if a customer order is cancelled by the sales representative and the distribution order is not this causes the purchasing team to have no visibility of the cancelled order and the purchases may still proceed. This is an issue where the chain of events occurring in Fig. 2 are not connected and transparency of information is not present to all stakeholders.